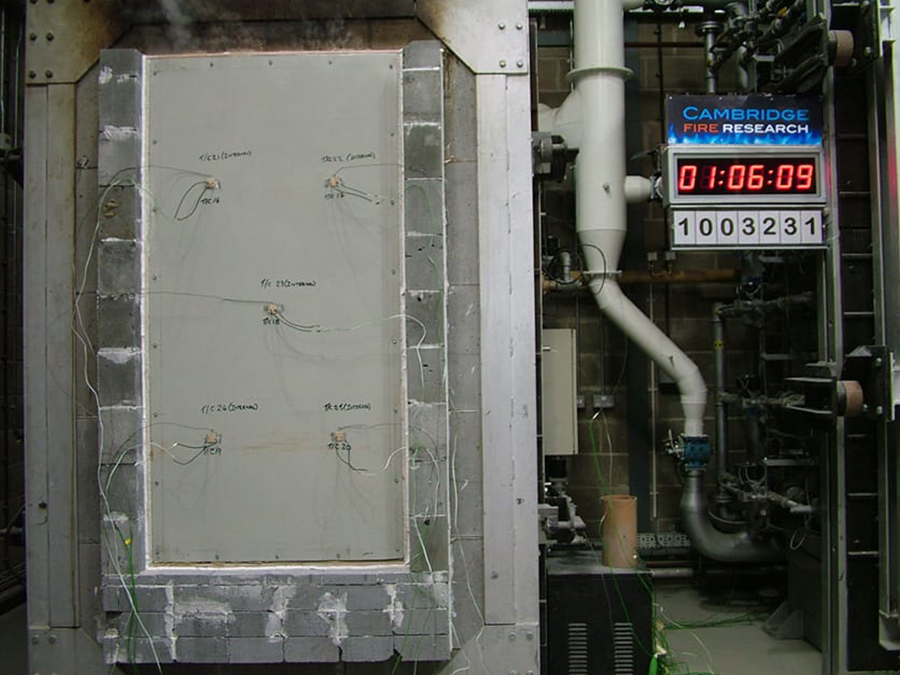

Full Scale Testing Vertical Elements

Exposed Area 3.0(h) x 3.0(w)m

The test method determines the fire resistance of non-loadbearing elements of building construction.

This test method evaluates the duration for which a wall construction can contain a fire within a compartment when tested against a standard set of temperature rise and pressure conditions. The test is carried out on a representative sample of the construction, affixed as in practice and incorporating joints and other features that would be required in normal construction and usage.

Common test durations are 30, 60, 90, 120, 180 and 240 minutes. Included within the test cost is a nominal overrun period of at least 10%. While not required by the test standard, this overrun may be required should you seek third party assessment of the test evidence. On request, the test can be continued beyond this point at a pro-rata fee.

To carry out an accredited test to BS 476: Part 22.

On request, dependent on your requirements for:

• Test duration

• Installation / Construction

• Additional measurements or instrumentation

• Reporting

Once you’ve booked a test, you can expect to receive a Test Date Booking Form – securing the booking date and agreeing the timeline for delivery and installation.

Closer to the time, we’ll ask you to complete a Customer Test Details Form, to confirm the exact details of the test. At this point we’ll also ask you to submit a full technical specification and CAD drawings in .dwg format.

The wall sample can be built by the test sponsor, or by our in-house build team – mechanically fixed within one of our 3m x 3m furnace restraint frames. During construction a member of our technical team will comprehensively document the materials and methods of construction.

If required, our in-house build team can prepare in advance an associated construction to reduce the size of the opening to suit your needs.

The sample is prepared for testing – measurements are taken, an array of thermocouples affixed, and positions marked for measurements to be taken during the test.

The frame is then mounted on the front of our 3m high x 3m wide vertical furnace so that one face of the sample is exposed to the fire – representing a compartment wall in practice.

The sample is evaluated for 2 criteria:

The result for each criteria is expressed as the number of whole elapsed minutes for which the sample maintains that ability.

Integrity is evaluated by:

Insulation is evaluated by:

Irradiance and lateral deflection are also measured and reported against the total number of elapsed minutes.

Exposed Area 3.0(h) x 3.0(w)m

Exposed Area 2.4(h) x 1.35(w)m

If required, CFR may be able to assist with procuring materials and specimen installation – Please enquire for details.

Get in touch or find us en route