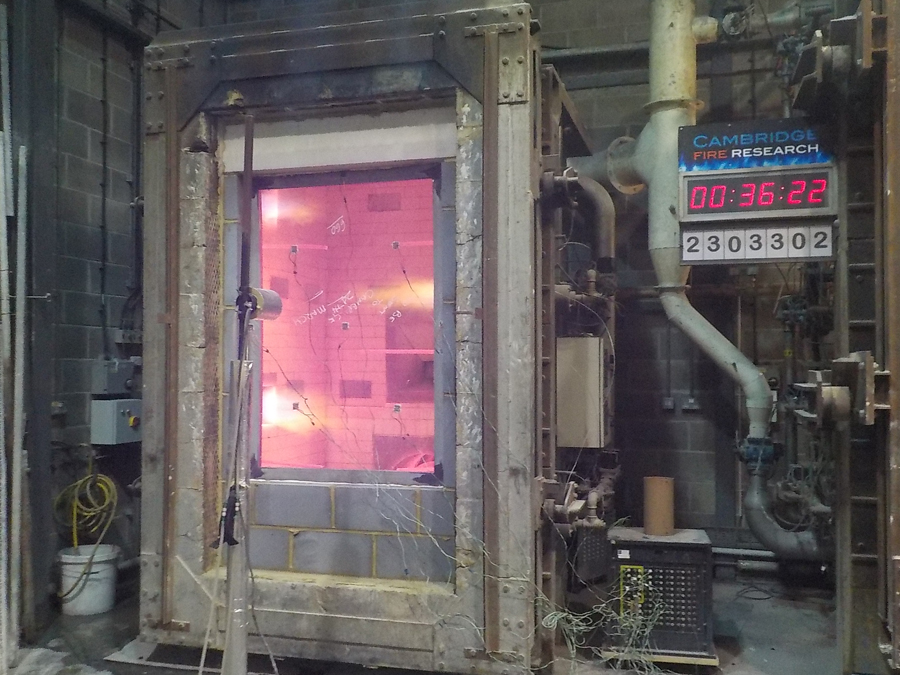

Full Scale Testing Vertical Elements

Exposed Area 3.0(h) x 3.0(w)m

The test method determines the ability of a representative specimen of a non-loadbearing wall to resist the spread of fire from one side to another.

All test bookings are provisional until confirmed by Cambridge Fire Research.

Before testing you will be contacted so that you can complete a Test Details Form summarising your test requirements.

You will also need to submit:

To carry out an accredited test to BS EN 1364-1:2015

On request – dependent on number of specimens and if installation required.

The test method determines the ability of a representative specimen of a non-loadbearing wall to resist the spread of fire from one side to another.

It is applicable to non-loadbearing walls, with and without glazing, non-loadbearing walls consisting almost wholly of glazing and other non-loadbearing internal external non-loadbearing walls.

The test takes place within or without a test construction, mechanically mounted to a restraint frame and hung on the front of a 3m high x 3m wide vertical furnace – representing a compartment wall in practice.

The test is carried out to the Standard temperature-time heating curve ISO 834, also known as the Cellulosic curve and to the pressure conditions as described in BS EN 1363-1:2020.

Common durations for this test methodology are 30 minutes, 60 minutes, 90 minutes, 120 minutes, 180 minutes and 240 minutes – each including a nominal overrun period intended to directly extend a products field of application.

The glazed elements are evaluated by the times in completed minutes for which the test specimen continues to maintain its separating function during the test without:

However, failure under all criteria shall be disregarded within 150mm of the free edge, unless in practice the free edge is unrestrained.

Insulation will be evaluated by the time in completed minutes for which the test specimen continues to maintain its separating function during the test without developing temperatures on its unexposed surface which:

Radiation will be measured and reported against the total number of elapsed minutes and when the measured radiation exceeded the values of 5, 10, 15, 20 and 25 kW/m².

Applicability of specimen sizes and other features – see clause A.4.

Applicability of supporting construction – see clause A.4.2.4.

Exposed Area 3.0(h) x 3.0(w)m

Exposed Area 2.4(h) x 1.35(w)m

If required, CFR may be able to assist with procuring materials and specimen installation – Please enquire for details.

Get in touch or find us en route